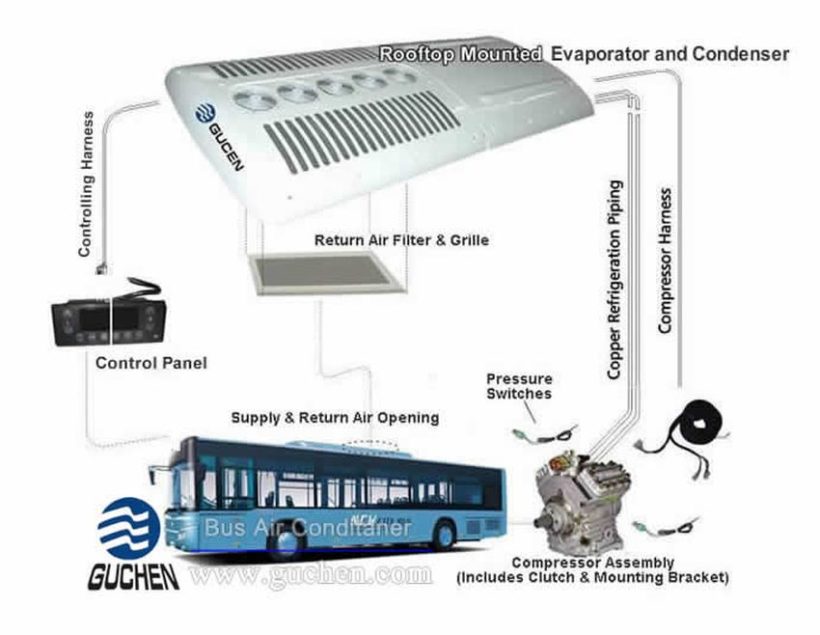

Would you like cold summer air or clear winter windows? If you need a functioning bus air-conditioning compressor click here. It is the air-conditioning system’s power unit that puts the coolant under high pressure before it pumps it into the condenser, where it changes from a gas to a liquid. Do you feel warm? Do not make hypotheses.

Not all problems with air conditioning are due to the low refrigerant system. Some are caused by problems with parts of the system. The compressor, for example.

Types of compressors

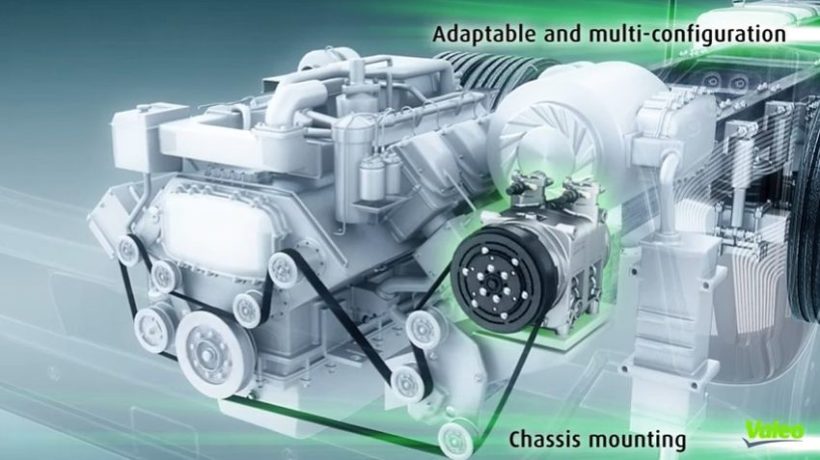

In bus air conditioning systems, there are basically four types of compressors. In window units and some central AC units, a rotary compressor is commonly used. They’ve been around for many years, and are both inexpensive and durable. In lower efficiency split air conditioners, a reciprocating compressor is the most common. They are relatively cheap, but not as long-lasting.

A scroll compressor in higher efficiency equipment is the most common type. They are very long-lasting and efficient, but usually more expensive.Variable speed compressors, commonly referred to as inverter drives, are the latest innovation. You can check an example of speed compressors on commercialaircompressor.ca. These are high-efficiency units at the top of the line, but they are usually the most expensive.

How often should I expect my air conditioning compressor to be replaced?

Usually driven by a serpentine accessory belt, an air-conditioning compressor sometimes squeals or squeaks before it breaks, but it can also stop working without any audible warning signs. In addition, the refrigerant can be leaked by a compressor, meaningless cool air or none at all. A competent bus mechanic is the best source for assessing if it is not working as problems with air conditioning can also be caused by coolant leakage somewhere else in the system, by a squeezing accessory belt or by corrosion in the air conditioning evaporator. If a leak occurs, adding refrigerant will not solve the problem.

Bus air-conditioning compressors often last a vehicle’s life, but they may fail due to wear out bearings, seals leakage and long-term corrosion, plus other factors. It should be a one-and-done fix if it needs to be replaced, not something that happens every 50,000 miles. It is likely that frequent compressor failure is caused by a misaligned accessory drive belt, a faulty pulley or another problem that creates undue stress.

Do I have to replace my air-conditioning compressor?

According to AircompressorsUSA, the air-conditioning compressor should last your bus’s life if you’re lucky. If it shows any of the above-detailed symptoms, however, you may need to replace it with a new air conditioning compressor (Sanden, Konvekta, Danfoss). Bus air-conditioning systems are sealed circuits and any loss of cooling capacity requires a complete system inspection.

The compressor is the core of the cycle of cooling. The cycle starts when it draws from the indoors in cool, low-pressure coolant gas. The sole function of the motor-driven compressor is to “squeeze” the refrigerant, raising its temperature and pressure to exit as hot, high-pressure gas from the compressor.