Some people will probably disagree that living in the 21st century is amazing. We do not want to say that everything in today’s world is perfect. However, advanced technology allowed people to improve different aspects of their life. Despite that, businesses from different industries have the opportunity to speed up their progress.

The automotive industry started to developed somewhere around 1860. So far, we have got thousands of different car models. However, this business field is not different from any other. Companies that participate in the industry also strive to follow the latest trends. That is the only way to improve the quality of the entire industry to another level.

By applying CNC machining to the accomplishment of everyday tasks, things have changed in the industry as well. You will manage to see different robotic, manufacturing, and design improvements in automotive production. Logically, that is one of the reasons why we got most of today’s modern vehicles.

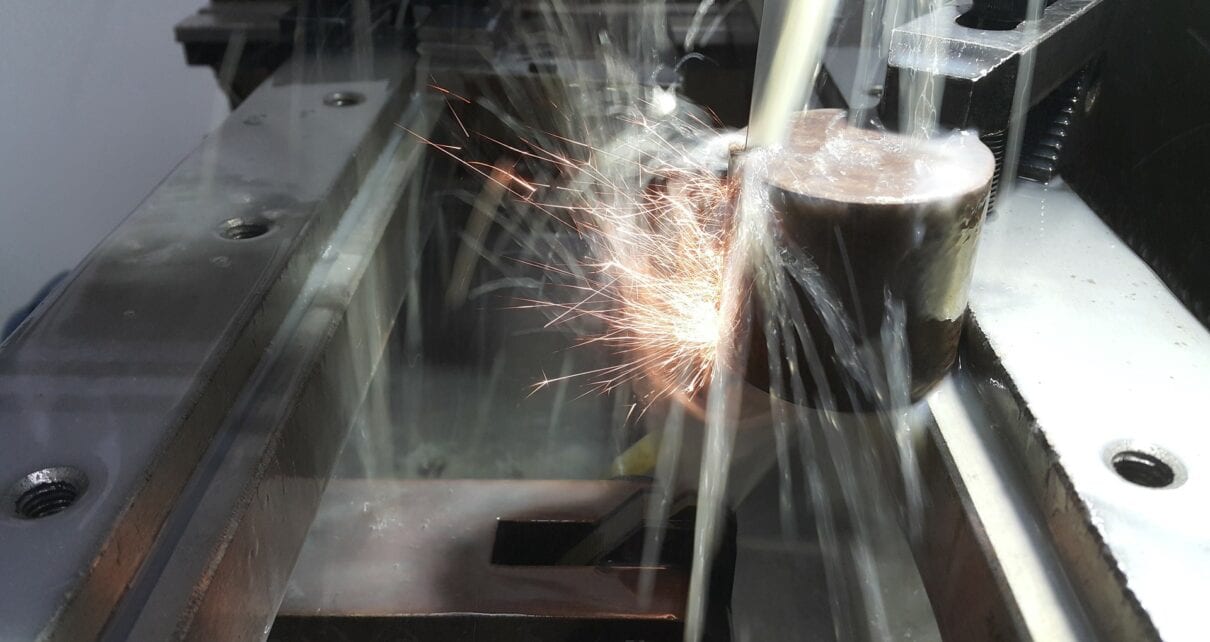

To make things clear, CNC machining is a modernized manufacturing process that can produce price metal and plastic car parts. The entire process may seem complex to people that are not familiar with this subject. Before everything, the digital model of a part converts into machine instructions. After that, the instructions go to the CNC machine. Thanks to different tools like mills, drills, lathes, and others, the machine cuts the material until it reaches the final result.

That is one of the reasons why many online retailers like Hamili Metal provide different metal and industrial products. They also managed to improve their business functioning thanks to the benefits CNC machining brings.

However, we are sure that the content above does not say the full story. That is the reason why we want to make a deep analysis of the use of CNC machining for the automotive industry. Let’s find out more about that subject together.

Benefits of CNC Machining for Automotive Industry

The manufacturers around the world are applying CNC machining into their business operations. It doesn’t need to surprise us why we have that type of situation in the world. The benefits that CNC machining can bring can potentially improve the performances of the overall business. We will highlight some of the most important ones.

1. Improvement of Precision

Reaching a tight tolerance for car parts was a huge problem for a long time. It was a costly operation that many companies around the world could not afford. Fortunately, this type of machining has the power to meet the tolerance for the engine and other components. Despite that, manufacturers do not struggle to produce different complex vehicle parts.

2. Faster Production

Traditional machining can be good for many reasons. However, working with them is almost always time-consuming. The production of car parts with basic machines usually last long. Fortunately, things are different when we talk about CNC machining.

The automated nature is the reason why they are capable of doing something like that. The need for labor-intensive and lengthy manual machining no longer exists. Part tolerance and material choice are two more factors that can make the production process even faster.

3. Repeatability

As we said, CNC machining is a computer-controlled process. That is the reason why repeatability is another advantage. It is one of the problems that companies from almost every field have. Fortunately, the automotive industry does not have a problem of that type. All car and car parts will be up to the same standards.

That is one of the essential reasons why some brands became so popular around the world.

4. Customization

People around the world have different tastes, requirements, and expectations. Because of that, the demand for customized parts became huge in all parts of the globe. That is one of the things that CNC machines have brought to the automotive industry. The manufacturers can meet the demands of every individual with no extra effort.

Things that Manufacturers Can Produce with CNC Machines

Here comes an even more interesting part. We managed to explain which benefits CNC machining brings to the entire automotive industry. However, we would also like to talk about applications that CNC machines can produce.

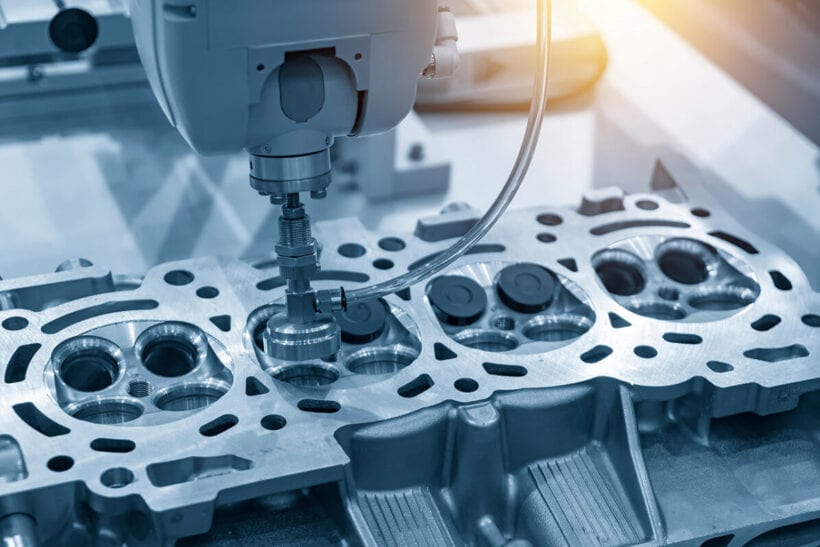

1. Cylinder Heads

We will start with cylinder heads because of one simple reason. You will manage to see that the motorsport industry also benefits from this technology. The CNC machines can produce the cylinder heads and engine blocks as well. In most cases, they are made of aluminum. In other words, it is a simple metal for the CNC machines and the entire job will finish promptly.

2. Interior Panels

Believe it or not, CNC machines also have the capacity to develop dashboard panels and other interior vehicle components. Keep in mind that dashboards require a high level of precision. For instance, it will help manufacturers to ensure that the gas gauge and speedometer suit perfectly after installation.

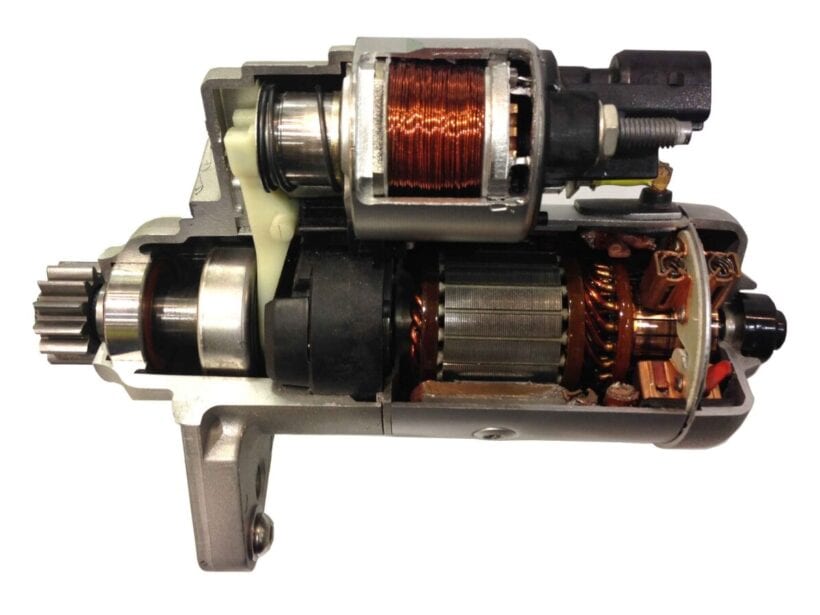

3. Starter Motors

Indeed, manufacturers still use different casting processes for different metal components. Yet, the CNC machine can also be a useful tool for different complex parts. One of those parts is the starter motor without any doubt. The entire process requires a high level of precision that CNC machines can provide. In that way, the parts like the starter motor will improve their durability, reliability, and overall performance.

4. Custom Parts

We already said that customization is one of the benefits that CNC machines can bring to the automotive industry. That is the reason why many manufacturers use them to produce customized components. Besides that, they will often use this opportunity to produce some rare replacement parts.

The best example of the CNC machining process we can see in the restoration of vintage cars. Together with the 3D printing process, CNC machining has the power to create all the one-off parts.

5. Gearboxes

In the end, we need to highlight that CNC machines can also develop different types of gearboxes. The reason why people use them for that purpose is probably obvious. They use the high level of precision and effectiveness that machines of this type bring. Things are not different when we talk about gearbox cast parts. With CNC milling as well as some drilling tools, the manufacturers can easily design them.