When referring to mechanical engineering, backlash is defined as being lost motion or clearance present in a mechanism. It is also known as play or lash and appears due to gaps present between utilized parts. Simply put, the maximum angle or difference through which the part in the mechanical system can be moved in a direction without having to apply appreciable motion or force to the next mechanical sequence part is backlash.

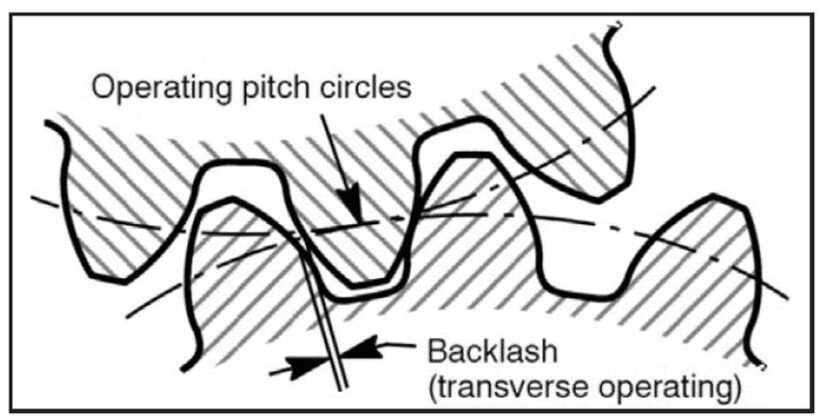

When referring to gear trains and gears, the clearance between the mated gear teeth is backlash. You can see it when movement direction is reversed. This is when lost motion or slack is taken up before motion reversal is done. You can hear this in railway couplings as the train starts to reverse the direction. Also, in the valve train that has mechanical tappets, as another example, some backlash is needed so that the valve can properly work.

Based on application, zero backlash gearbox manufacture may or may not be needed. Usually, it is unavoidable for the mechanical couplings, even if effects can be compensated for or simply neglected. In various applications, the goal is to get a theoretical zero backlash. In reality, some of them has to be present in most applications in order to prevent a jam. According to rozum.com backlash presence is needed due to various reasons, including manufacturing errors, thermal expansion, deflection under load and lubrication.

There are different factors that affect how much backlash is needed in the gear train. This includes pitch, helix angle, center distance, run-out, tooth thickness and profile. If the accuracy is higher, the backlash needed is smaller. Most commonly, it is created through cutting teeth deeper, right into gears than what the ideal depth is. You can also introduce it in a system by increasing distances between gears and centers.

Usually, if it appears because of tooth thickness changes ends up measured with the use of pitch circle. The backlash that appears due to center modifications is connected with the machine’s speed. Also, the machine material can have an influence on everything.

The standard practice with its settings is to make an allowance for 50% of what is needed in tooth thickness for every single gear. In the event that the pinion gear is much smaller, all the backlash is normally added to the gear that is the largest. This is needed to maintain as much maximum strength as is possible in the teeth of the pinion. The extra material that is removed as gears are made depends on teeth pressure angle. If the angle is 14.5 degrees, equals are moved to get the desired backlash. If the angle is 20 degrees, you have 0.73 times needed backlash.

Generally, the average backlash will be defined by having the number 0.04 divided by the value of the diametral pitch. Minimums used can be at 0.03 and maximums can be at 0.05. It is cumulative in the gear train. When reversing it, it needs to be turned before a final driven gear can start to rotate.